fast sincere

We turn ideas into amazing packs

fast sincere

We turn ideas into amazing packs

The cold cut is divided into a cold cut of the pull piece, a cold cut of the extruded piece, and a cold cut of the extruded piece.

The cold cut of the pull piece is plasticized by an open mill, and after cooling, it is diced by a flat granulator. This method has a large output and is suitable for various shapes of plastic.

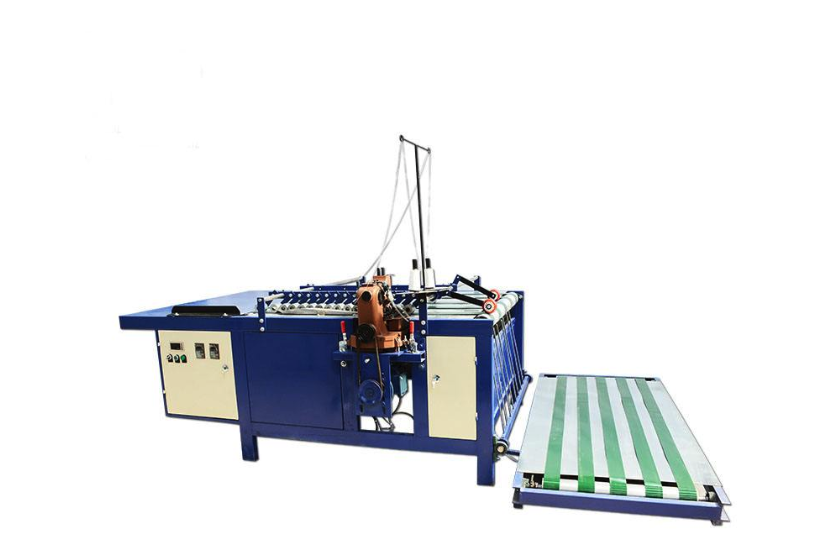

Extrusion strips are cold cuts. The material is extruded through an extruder to extrude strips or sheets. The strips are cooled by a cooling water tank, and then the moisture of the surface of the strips is blown by a wind mill, and sent to a pelletizer by a pulling device.

There are several important reasons why the popularity of flex packaging continues to increase a...

It is undeniable that custom packaging bags occupy a very important position in many production-o...