fast sincere

We turn ideas into amazing packs

fast sincere

We turn ideas into amazing packs

Opp bag packing is produced by first making a melt of high molecular weight polypropylene into a sheet or a thick film through a narrow machine head, and then in a dedicated stretching machine at a certain temperature and set speed, simultaneously or in minutes. The film is stretched in two perpendicular directions and subjected to appropriate cooling or heat treatment or processing. The surface energy of the OPP film is relatively low and the adhesion is not strong.

OPP is tasteless, harmless, has high tensile strength, impact strength, good toughness and certain transparency. It can be printed in a color to give a beautiful appearance, so it is often used as a material for composite films.

The OPP film obtained by different processing methods of OPP film has different properties. The opp bag packing produced by the flat film method has a higher tensile ratio than the tubular film method, and the film thickness uniformity is also good. In order to obtain better comprehensive performance, it is usually produced by a multi-layer composite method during use. BOPP can be combined with a variety of different materials to meet specific application needs. For example, BOPP can be combined with LDPE, PE, PT, PO, etc. to obtain high resistance to gas, moisture, transparency, high temperature and low temperature.

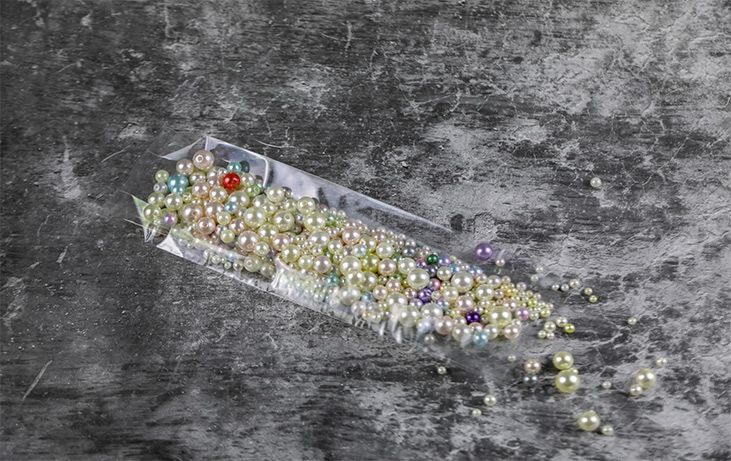

Opp bag packing is also widely used, some for cosmetics, mask paper, small jewelry, cards, packaging clothes, shoes and hats or magazines.

Some can even hold food, such as: bread, miscellaneous grains, dried fruit. This bag is non-toxic, tasteless, and is a food-grade bag that can be used with confidence.

There are several important reasons why the popularity of flex packaging continues to increase a...

It is undeniable that custom packaging bags occupy a very important position in many production-o...